Electronics Construction Techniques, Hints & Tips

Understand some of the basic techniques as well as hints and tips to help you construct electronic circuits and equipment more easily and with a better finish.

Home » Construction & manufacture » this page

Construction Hints & Tips Includes:

Practical hints & tips overview

How to make twisted pair wire

How to drill cases that are painted

How to use heat shrink sleeving

How to tidy wiring with looms

How to straighten kinked connecting wire

Bending & forming axial component leads

Using ferrite rings to cure power line interference

Electronics construction whether as a general hobbyist, radio amateur, maker, or a professional electronics engineer is an essential skill.

Perfecting the art of electronics construction will help projects turn out better, perform better and often be more reliable.

There are many basic techniques, from solering and circuit assembly to those required for various aspects of wiring, mechanical work and much more.

These techniques and hints and tips are an essential part of the electronics scene, but like anything else, they can take time to learn.

These pages - often incorporating videos - are aimed at bringing together pages detailing the various techniques, short-cuts, and hints and tips to help anyone who is interested in electronics construction.

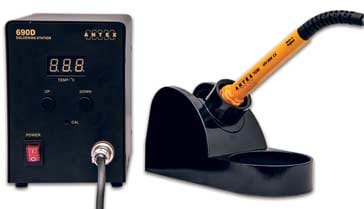

Soldering

Soldering is one of the key activities in any construction project. While automated methods using surface mount components are used for large scale manufacturing, manual soldering is still widely used for small production runs and for hobbyist and prototyping, etc.

Soldering is almost an art, and when managed correctly, any job can look neat as well as providing the good reliable connections that are needed.

The use of a good soldering iron as well as having the right technique are both essential elements needed to achieve the required results.

There are many other skills as wella s hints tips and shortcuts that can help in getting a better electronics project completed faster.

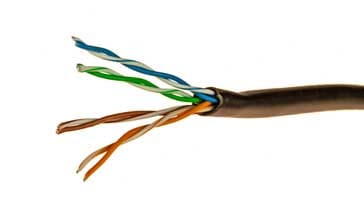

How to make twisted pair wire

Twisted pair wire or cable is often needed as it helps in considerably reducing stray radiation and pickup. Twisted pairs are often used used for cables used for data transmission. For example,they are used within Ethernet cables.

However they can also be used in many other areas where a level of screening is required. They may be required for a short data link within a room, or an even shorter length within an item of electronic equipment such as a cosntruction project, etc.

Fortunately it is very easy to make a twisted pair wire from two lengths of wire.

How to make neat holes in ready painted cases / boxes

It is often good to house an electronics construction project in a nicely pained box or case.

Certainly I've found that it not only makes the project look nicer, but it lso enables it to operate better because the wiring is not running everywhere and open to the possibility of short circuits, etc.

It is also good to make the job look as neat as possible. However when drilling pained or nicely finished panels there is a distinct possibility of scratching them with swarf, the drill itself, or anyone of a number of other things.

To overcome this, the case can be protected using masking tape - this can even be used to mark the drill holes, etc.

How to use Heat Shrink Sleeving

Heat shrink sleeving can be really useful when building a project, or for a large variety of jobs associated with electronics.

It can be used to cover a joint in a wire, a terminalpoint that needs insulating, for keeping wires in a cable together, as an ident on a wire or cable . . . the list goes on.

In our page on heat shrink sleeving, we show you how to use it and the tools needed.

Using wiring looms

Sometimes when building a project, a lot of cables may run together and it would be good to keep them together, neat and tidy.

Cables ties can be used, but also for a very much neater job, cable looming cord can be used. There are special ways of doing this to provide the best finish.

How to straighten kinked & bent wire

When building an electronics project, often a length of wire may be needed, and it might be necessary to re-use a length that might have already been used.

The trouble with this can be that the wire can have kinks or bends in it, and as a result it might not be suitable to re-use.

It is really easy to remove these kinks and bends as we show in this page with its embedded 'How to . . ' video.

Bending & forming axial component leads for PCBs

When building a printed circuit board, it is usually necessary to lay the component flat on the board and have the component leads neatly bent round.

On any given board, the hole spacing for a particular type of component should be the same wherever they are in the circuit.

For instances like these it is useful to have a method of neatly bending all the component leads to exactly fit the board and have a sharp corner.

There are also some key do's and don'ts as well - key points of which to be aware.

'Helping hands' holders when you need three hands

When soldering wires together of for a host of other jobs when constructing electronic circuits, it helps to have a third and sometimes even a fourth hand.

Did you know that you can buy special accessories to help with this. Called a helping hands holder, these items come ina variety of forms, but the ones used here have a couple of crocodile / aligator clips which can be angled to position the item in the correct position while you solder the joint etc.

These helping hands accessories are available from a variety of distributors and outlets and can be bought relatively cheaply.

Understanding some of the techniques required for building and assembling electronic equipment and projects helps in many areas. Some of the basic skills as well as some know how about the various techniques available helps provide a good basis for understanding, repairing and building all sorts of electronics based items.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Construction Ideas & Concepts:

Soldering

SMT component soldering

ESD - Electro-Static Discharge

PCB manufacture

PCB assembly

Return to Constructional Techniques menu . . .