Understanding Inductor Specifications & Parameters

When selecting inductors it is necessary to understand the various specifications, parameters and figures found in the datasheets for these electronic components to select the right one for an electronic circuit design.

Home » Electronic components » this page

Inductors Includes:

Inductor types

Inductor specifications

How to select the right inductor

Ferrites

Ferrite beads

Transformers, types, applications

Like any electronic component, there are several parameters and specifications that are associated with inductors. It is necessary to understand the various specification parameters and inductor characteristics when deciding upon the required component.

The inductor parameters and specifications enable the component to be satisfactorily described and correctly used within and circuit design.

The various parameters that can be used enable the inductor performance to be fully specified so that it can confidently used within the required circuit.

It is also necessary to understand the spurious responses as well because these can be as important as the basic specifications, and could significantly change the operation of any electronic circuit design.

From air cored inductors, to toroidal inductors and from leaded electronic components to surface mount device versions, the same basic specifications and parameters apply.

As many inductors are used in RF designs, it is often very important to understand the aspects of these electronic components as the frequencies rise into the radio frequency portions of the spectrum, and various spurious aspects can start to have a major impact on their performance.

Inductance specification

The key parameter for any inductor is obviously its inductance. The inductance is the property of the inductor that tends to oppose any change in the current flowing.

The SI unit of inductance is the henry, H. The inductance of a circuit is one henry if the rate of change of current in a circuit is one ampere per second and this results in an electromotive force of one volt.

The actual level of the inductance is influenced by many factors including the number of turns on the coil, coil diameter and in particular the core used within the coil.

As a one henry coil would be very large and only used in very low frequency applications, inductor parameters are more normally specified in terms of microhenries,, µH. Other values may also be used and can be converted according to the table below:

| Value | Value in terms of microhenries |

|---|---|

| 1 henry | 1 000 000 µH |

| 1 millihenry | 1 000 µH |

| 1 nanohenry | 0.001µH |

Although some inductors and especially large inductors may have specific values, but for many others, especially the lower values where standard inductors can be bought, the values correspond to the E series.

This gives a set of standard values for inductor that can be incorporated into electronic circuit designs or RF designs.

By using the standard E series values, standard components can be obtained which are cheaper than any that might have been made specially. Generally the inductors that conform tot hese values are the small leaded or surface mount inductors.

| E3 Standard Component Value Series | ||

|---|---|---|

| 1.0 | 2.2 | 4.7 |

The E3 series values are the most widely used and hence these values will be the most common values used for these electronic components. They are particularly useful for inductor values that are not in any way critical. By keeping to this series, the number of different inductor values in any electronic circuit design can be reduced and this can help reduce manufacturing costs by reducing inventory and the additional management and set up required for additional component types in a design.

| E6 Standard Series | ||

|---|---|---|

| 1.0 | 1.5 | 2.2 |

| 3.3 | 4.7 | 6.8 |

The E6 series inductor values are also widely used within the industry. They provide a wider range of common values that can be used in electronic circuit designs and this can be very useful for many analogue designs.

| E12 Standard Series | ||

|---|---|---|

| 1.0 | 1.2 | 1.5 |

| 1.8 | 2.2 | 2.7 |

| 3.3 | 3.9 | 4.7 |

| 5.6 | 6.8 | 8.2 |

Series above E12 may be available, but they are likely to be less common, more costly and possibly more difficult to obtain and as a result they are more likely to have longer lead times.

Tolerance specification

Like all components, inductors have a certain tolerance - the perfectly exact values cannot be realised in a real world.

As a result, all inductors have a certain tolerance attached to their specification. Generally, the tighter the tolerance, the more expensive they are, and it can also lead to a greater difficulty in obtaining them.

Standard values for the tolerance of small leaded or surface mount inductors can be ±20%, ±10%, and ±5%. Variability levels in winding and core material make it hard to achieve the sort of tolerance levels available for resistors and some capacitors.

Also, it will be found that there are many inductors without any tolerance marking - these can be assumed to have a tolerance of ±20%.

Normally it is easier to obtain an inductor with a reasonable tolerance level and then, if necessary, have an adjustable capacitor to trim the resonance, etc of the RF design.

DC Resistance

Another important inductor parameter is the DC resistance it exhibits. As inductors are often manufactured from very thin wire, the DC resistance can sometimes be significant.

Even when thicker wire is used, the resistance of the inductor is still a very important factor because it can significantly affect the overall performance of the component.

The DC resistance can be considered to be in series with the pure inductor for the sake of most circuit simulations, although in reality it is distributed throughout the inductor.

The DC resistance, measured with a steady current is normally specified in Ohms, Ω and typically given as a maximum value as it is sometimes difficult to control accurately.

Saturation Current

The saturation current is another parameter or specification which is of importance for an inductor. Obviously it is very important where high current levels are involved, but can also catch the unaware out in other electronic circuit design situations as well.

In an inductor it is possible to saturate the core because there is a limit to the level of magnetic flux a magnetic core such as iron, ferrite or another compound can take. When this occurs the relative permeability falls and in turn this causes the level of inductance falls.

The saturation current is generally taken to be the current at which the level of inductance falls by a specified amount. Figures of 10% are often used for inductors with ferrite cores and 20% for those with iron powdered cores.

Incremental current

Often inductors run with a bias current passing through them. For example, this may be the quiescent current for a transistor collector where the inductor is in the collector circuit itself. There is a drop in inductance that is caused by this current and it is necessary to understand this so that the circuit will be able to operate satisfactorily even when the DC bias current is flowing.

The incremental current inductor parameter is generally taken as the DC bias current flowing through the inductor that causes the inductance to fall by 5% from its initial value with zero bias.

The value for the incremental current parameter or specification indicates the level where a further increase in current would cause the inductance to fall by a significant value.

The incremental current value for an inductor is most important when using ferrite cores as they exhibit a much faster reduction in inductance with increasing current than other forms of core such as a powered iron core.

Rated current

Another important inductor parameter is the rated current. This specification is the maximum continuous current that the inductor can withstand. Generally the limiting factor for this parameter is the temperature rise of the inductor.

With thin wire being used in many inductors to keep the size to a minimum, the current flow can result in power being dissipated in the inductor with the result that the temperature rises. Undue temperature rises can reduce the reliability or even cause catastrophic failure in some circumstances.

Core permeability

The permeability of the inductor core is a key parameter. It governs the inductance of the inductor for a given inductor geometry. Higher permeability core materials result in the inductor providing a higher level of inductance.

The core material as well as the core shape, size and geometry affect the overall effective permeability, and therefore these factors also need to be taken into consideration as well.

Winding self-capacitance

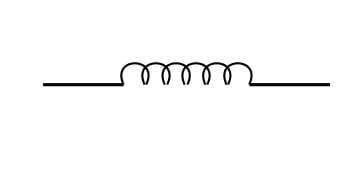

The inductor self-capacitance or distributed capacitance is a particularly important parameter in many applications. It arises from the fact that apart from adding inductance, the wires also have a small but appreciable level of capacitance between each other.

The diagram shows individual capacitors within the inductor as this a simplified way of showing the self-capacitance. However the capacitance is distributed throughout the whole inductor and it is not separate capacitance.

The level of capacitance depends on the area of the wire, the distance between the two wires and the permittivity of the material between them. Normally the level is relatively low, but it manifests itself to an external circuit as a small amount of capacitance across the inductor. This gives rise to what is termed the self-resonant frequency of the inductor.

Self resonant frequency

In view of the self-capacitance or distributed capacitance, the inductor forms a parallel resonant circuit as shown.

At the point where the inductor resonates the inductive reactance and the capacitive reactance will cancel each other out, and the overall impedance of the circuit will fall to a value governed by the DC resistance of the circuit..Below the resonant frequency the inductive reactance will dominate, whereas above the self-resonant frequency the capacitive reactance will dominate.

As a result inductors are normally used below their self-resonant frequency to ensure that the effects of self-resonance are not experienced.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Electronic Components:

Batteries

Capacitors

Connectors

ADC

DAC

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .