DIN 41612 Connector

The DIN 41612 connector has been and remains a mainstay connector for the electronics industry connecting cards to cable forms and other boards.

Home » Electronic components » this page

Connector Technology Includes:

Connector basics

Connector types

Specifications

Selecting the right connector

D-type connector

IEC power connector

Jack connector

XLR connector

IDC connector

PCB edge connector

DIN 41612 connector

The DIN 41612 connector is an industry standard connector widely for connecting boards, modules to another board such as a motherboard in a system.

The connector conforms tot he DIN 41612 standard - DIN is the Deutsches Institut für Normung i.e. the German Institute for Standardisation. In view of the popularity of the connector and its worldwide usage, the standard has been adopted by other bodies and may be referred to as IEC 60603-2 and EN 60603-2. Despite this adoption, the connector is still known as the DIN 41612 connector.

The DIN 41612 connector finds particular applications in systems that have an open architecture where cards, modules and rack systems may be obtained from a variety of manufacturers and suppliers. For this to be able to work, the various elements from different manufacturers must be able connect reliably, and for this a standard connector is required.

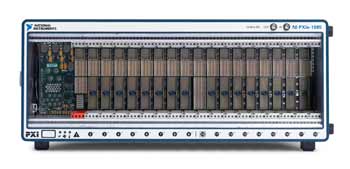

The DIN 41612 connector is widely used in systems from VME bus to VXI Bus, Multibus, Futurebus and many more. It is used for many Eurocard applications. For the test and instrumentation business it is used in PXI.

What is the DIN 41612 connector: the basics

The DIN 41612 connector is a high pin-count connector suitable for providing connections from cards to motherboards in bus based systems.

The connectors have contacts arranged in rows, typically one two or three, with two and three being the most common. These rows are labelled, a, b, and c, for example a pin may be numbered 21a, or 22b, etc., dependent upon the position and the row.

Typically the rows have 16 or 32 contacts per row allowing permutations of 16, 32, 48, 64 or 96 contacts. The pins are on a 0.1 inch spacing pitch (2.54 mm).

The insertion and removal force are defined and there are three durability grades that are available.

To aid construction of motherboards and the like, the female DIN 41612 connectors have press fit contacts options available rather than solder pin contacts. This helps avoid thermal shock to the backplane during manufacture.

DIN 41612 connector types

There are several different types of DIN 41612 connector that are referred to within the data sheets. These include Types B, C, D, F, M, Q and R. There are also the standard DIN sizes as well as half, third, and expanded sizes to meet all the requirements that are submitted by various equipment manufacturers.

| DIN 41612 Connector Types | |||

|---|---|---|---|

| Connector Type Designation |

Male / Pins | Receptacle | Pin Configuration |

| B | Right angled | Straight | 2 x 32 |

| C | Right angled | Straight | 3 x 32 |

| R | Straight | Right angled | 3 x 32 |

DIN 41612 connector classes / levels

The DIN41612 connector is classified according to the standard of the connector. There are two different IEC standards that can be used, namely IEC 60-603 and IEC 61 076-4 113. Each provides slightly different test conditions, but in both cases, Class 1 or Level 1 provide the highest quality and reliability. They are obviously are more expensive, and this is mainly as a result of the thicker gold plating on the contacts.

- IEC 60 603-2:

- Class 1 / Level 1 DIN 41612: This is the most robust form of DIN 41612 connector and for this the connector undergoes 250 mating cycles, it is then exposed to 10 days of gas using sulphur dioxide and then another 250 mating cycles. After this there should be no visual abrasion of the contact material and no functional impairment, i.e. increase in contact resistance.

- Class 2 / Level 2 DIN 41612: This is the next level down in the connector range. The connector undergoes 200 mating cycles, it is then exposed to 4 days of gas using sulphur dioxide and then another 200 mating cycles. After this there should be no visual abrasion of the contact material and no functional impairment, i.e. increase in contact resistance.

- Class 3 / Level 3 DIN 41612: This is the lowest level of connector and for this the connector is able to withstand 50 mating cycles and then is given a visual inspection for which there should be no visible signs of wear., and there should be no functional degradation.

- IEC 61 076-4-113:

- Class 1 / Level 1 DIN 41612: Again, this Level or Class is the most robust form of DIN 41612 connector under this testing regime. The connector undergoes 250 mating cycles, it is then exposed to 10 days of gas using sulphur dioxide and then it undergoes another 250 mating cycles. After this there should be no visual abrasion of the contact material and no functional impairment, i.e. increase in contact resistance.

- Class 2 / Level 2 DIN 41612: This level of connector is not to the same specification and as a result it is lower in cost. For the testing, the connector type undergoes 125 mating cycles, it is then exposed to 4 days of gas using sulphur dioxide and then it undergoes a further 125 mating cycles. After this there should be no visual abrasion of the contact material and no functional impairment, i.e. increase in contact resistance.

Normally when mention is made of the DIN 41612 classes or levels this will refer to the IEC 60 603-2 testing regime, although some manufacturers offer connectors classified under both regimes.

Typically Class 1 is the highest and used for aviation and military applications, class 2 is for industrial, and class 3 is for more general use where the number of insertions is likely to be low and where reliability is not so critical.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Electronic Components:

Batteries

Capacitors

Connectors

ADC

DAC

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .