How to Develop a Successful Test Strategy

How to develop a successful test strategy or test automation strategy, write a test strategy document and template and improve performance of the process.

Automatic Test Equipment, ATE Includes:

ATE basics

Automated optical inspection, AOI

Automated X-ray inspection, AXI

In-Circuit test, ICT

Functional test, FATE

Developing test strategy

The development of a test strategy / process or testing strategy for an electronics product is just as important as the development of the product itself. It is an unfortunate fact of life that not all products will work once they have been manufactured and it is necessary to test the product before it is shipped to ensure that it is operational.

The test strategy or testing process will need to be developed around the product, and the available equipment. When creating a testing strategy it is necessary to take account of many other aspects of the product including its design, the complexity of the boards and many other factors. It may be necessary to ensure that elements of the design are changed to enable testing to be accommodated more easily and in a more cost effective manner. As a result it is necessary to develop the test strategy from the earliest stages on the development of the product.

Elements of developing a test strategy

In order to create a test strategy, it is necessary to start at the beginning of a project and then carry the development and implementation forward throughout the whole of the development and production lifecycle. In order to ensure that the testing strategy is carried forward, it is wise to create a test strategy document, and update this as the development and production elements of the project move forward.

The main elements of the test strategy lifecycle may include the following:

- Analyse the product: One of the first tasks to undertake is to completely review the proposed product. It will be possible to gain a good idea of the construction of it, and form a view of the anticipated components and technologies it should be possible to estimate the anticipated failure rates.

- Review available test equipment: While many would like to tailor the test equipment to the product and buy new test equipment, this is not normally possible. It is normally necessary to re-use existing test equipment and to design the product so that it is optimised for the test equipment that already exists. With a knowledge of the technologies used in the proposed product it will be possible to assess the existing test equipment to ensure it will be suitable for testing the new product.

- Review test opportunities: It will be necessary to review the areas in which assemblies can be tested, both during the pilot production runs when more failures would be expected as well as later in its life when the processes will have matured and the line settled down.

- Create test strategy document: In order to define what needs to be achieved it is necessary to create a test strategy document. This will set down the aims of the test strategy in a form that can be reviewed and then implemented. It is vital that all parties agree to this so that any design for test strategies can be implemented during the early design stages for the product.

- Implement test strategy: It is necessary to implement the test strategy from the earliest stages of the deign of the product. Elements of design for test will need to be implemented from the concept stages of the product through to the time when printed circuit boards and ASICs are committed. By ensuring that any design for test measures are introduced, the testing of the product can be greatly simplified and the test coverage increased to a level where few failures are missed.

- Collect metrics: One key element of any test strategy is to collect metrics. In this way commonly occurring problems can be seen and rectified. In this way the production process can be improved and costs reduced. Only by collecting metrics and analysing them quickly can process improvements be achieved.

- Review and change test strategy and testing: One of the key elements in any test strategy is to incorporate regular reviews of the product and be prepared to change even after the product has been in production for some while. This costs additional money and once a product has completed its development, this is rarely available and as a result costs may be higher than necessary because the testing is not continuing to be optimised. It is normally advisable to make changes to the test strategy once a product has been in production. It may be possible to omit some tests which rarely produce results or it may be necessary to introduce others to reduce fault find time. These improvements to the test strategy can only be implemented if funding is available.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Test Topics:

Data network analyzer

Digital Multimeter

Frequency counter

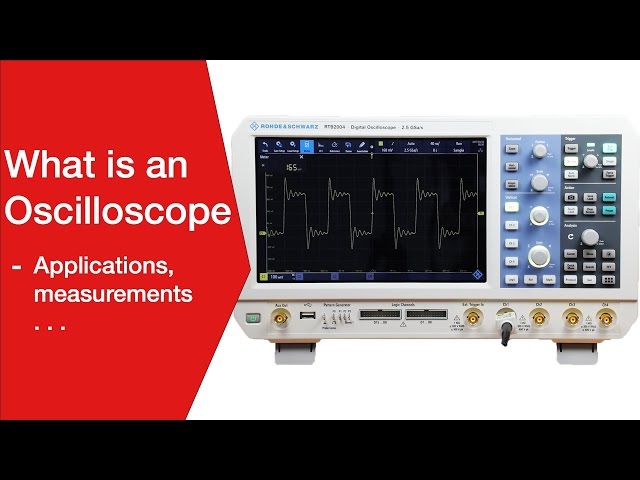

Oscilloscope

Signal generators

Spectrum analyzer

LCR meter

Dip meter, GDO

Logic analyzer

RF power meter

RF signal generator

Logic probe

PAT testing & testers

Time domain reflectometer

Vector network analyzer

PXI

GPIB

Boundary scan / JTAG

Data acquisition

Return to Test menu . . .