Wheatstone Bridge Strain Gauge

The Wheatstone bridge circuit is often used in many test and sensor applications, but one common use is as a Wheatstone bridge strain gauge.

Wheatstone Bridge For Test Includes:

Wheatstone bridge test applications basics

Strain gauge

One common use of the Wheatstone bridge is as a strain gauge. Its circuitry and mode of operation lend it particularly well to use as a strain gauge.

Strain gauges have a huge number of uses as they are used to measure bending in materials and structures. As a result they are widely used in civil engineering, in industrial plant monitoring, electrical motor operation and a huge number of other areas.

Wheatstone bridge as a strain gauge

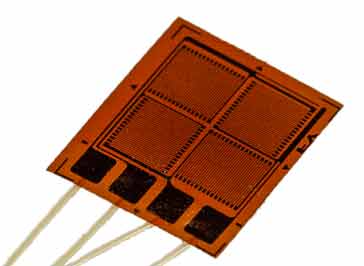

Essentially strain gauges consist of a wire or metal foil for which the resistance changes as the resistive element is deformed, either stretched or compressed.

When the strain gauge is tensioned or stretched this increases the resistance of the element slightly, and when it is compressed, it similarly decreases in resistance.

Strain gauges are often attached to structures so that they can detect any movement that will apply a "curve' to the strain gauge and in this way the elements will stretch and compress causing the resistance in the elements to change and hence allowing a measurement to be made.

This resistance changes are often small, and therefore an accurate and reliable means of detecting these changes is needed.

The Wheatstone bridge is the ideal topology for achieving this reliably and accurately.

Practical aspects

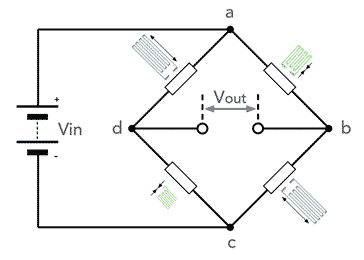

When using a Wheatstone bridge as a strain gauge, the gauge configuration is typically arranged in a full bridge configuration, i.e four active elements within the Wheatstone bridge itself.

By arranging the sensor as a full bridge, the best output can be obtained and typically this might be a few millivolts for each volt applied across the bridge.

As different elements of the strain gauge will be subject to compression and extension, these are arranged opposite each other to provide the required circuit operation.

Load cell

A Wheatstone bridge strain gauge can be attached to a bar of known characteristics and used to measure the load or weight of an item.

Knowing the characteristics of the strain gauge and the output it gives for a certain deflection and combining this with a bar with known bending characteristics, it is possible to make a load cell.This will give a known amount of bend for a given weight, and then the bridge circuit will give a known output for a given bend.

In this way, it is possible to weight anything that is placed upon the bar, making sure there is an arrangement to ensure the load from the weight is applied at a specific point. This will overcome issues caused by the bending moment being greater as the distance from the fixed point increases.

Wheatstone bridges lend themselves to being used as the key element in strain gauges and load cells. They are easy to manufacture and give accurate readings, enabling them to be sued in a wide variety of different situations.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Test Topics:

Data network analyzer

Digital Multimeter

Frequency counter

Oscilloscope

Signal generators

Spectrum analyzer

LCR meter

Dip meter, GDO

Logic analyzer

RF power meter

RF signal generator

Logic probe

PAT testing & testers

Time domain reflectometer

Vector network analyzer

PXI

GPIB

Boundary scan / JTAG

Data acquisition

Return to Test menu . . .