Design for Automated Optical Inspection & Test

Design guidelines for Automated Optical Inspection, AOI and Automated X-Ray Inspection, AXI, as part of a design for test, or testability strategy.

Automatic Test Equipment, ATE Includes:

PCB inspection techniques

Automated optical inspection, AOI

Automated X-ray inspection, AXI

Design for AOI test

See also:

ATE basics

In-Circuit test, ICT

Functional test, FATE

Developing test strategy

AOI, automated optical inspection is a particularly successful method for inspecting printed circuit board, PCB assemblies once they have passed through a soldering process. AOI is able to detect defects including solder joint problems and as well as a variety of other problems. In order to be able to detect these defects efficiently and with a minimum number of no problem found instances, it is necessary for the board or assembly to have undergone a design for automated optical inspection or test process.

In order to ensure that the AOI test can be performed efficiently a number of guidelines can be followed in the design and layout of the printed circuit board. This will make the automated optical inspection more effective and less likely indicate problems that do not exist. By implementing these design for test features, testing can be made more effective and this will result in swifter testing, less rework and overall reduced costs.

Design guidelines for AOI testing

There are many steps that can be taken to improve the way in which AOI, automated optical inspection systems may perform. Essentially the success of an AOI system depends upon the way in which the system camera is able to view the board, and the image processing is able to handle images and detect any defects.

The ideas mentioned below are some ideas that can be implemented to improve the AOI performance:

- Ensure visible access to all areas of the board: In some instances tall components or other features of the PCB assembly may cause areas of the board to be less visible. When designing the PCB, ensure all areas are easily visible for the AOI system.

- Maintain consistent component sizes: Despite the nominal sizes specified for many components including capacitors and resistors, the actual sizes vary slightly between manufacturers.

- Use standard component pads: Use standard component pads wherever possible as this means that the AOI processor only needs to sore one profile for a good joint.

- Do not use overlapping pads: In some instances it may be convenient to merge two component pads together. If possible this should be avoided as overlapping pads may show a different joint profile and give false defect indications.

Summary

Implementing design for automated optical inspection ideas will improve the reliability of any AOI testing that is undertaken. If design for AOI is not adopted, areas of the board may not be sufficiently inspected and defects may pass this stage of the manufacturing process. If testing and inspection is to be undertaken, it is always better to ensure it can be achieved as effectively as possible. By accommodating the requirements for AOI in the early stages of design will assist in making the manufacturing process as efficient as possible.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Test Topics:

Data network analyzer

Digital Multimeter

Frequency counter

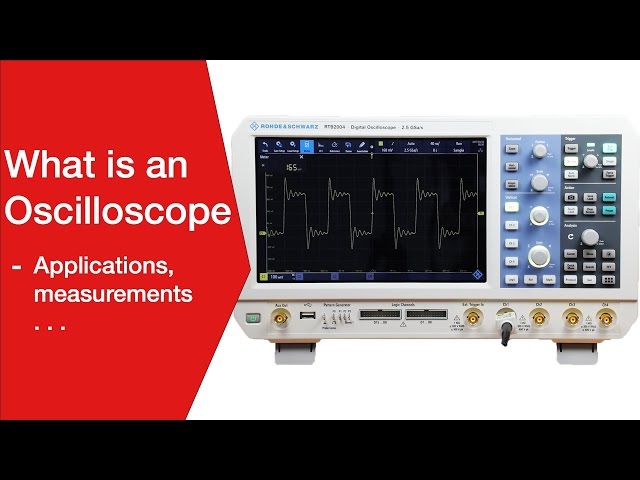

Oscilloscope

Signal generators

Spectrum analyzer

LCR meter

Dip meter, GDO

Logic analyzer

RF power meter

RF signal generator

Logic probe

PAT testing & testers

Time domain reflectometer

Vector network analyzer

PXI

GPIB

Boundary scan / JTAG

Data acquisition

Return to Test menu . . .